- #Determine if teamviewer hacked update

- #Determine if teamviewer hacked code

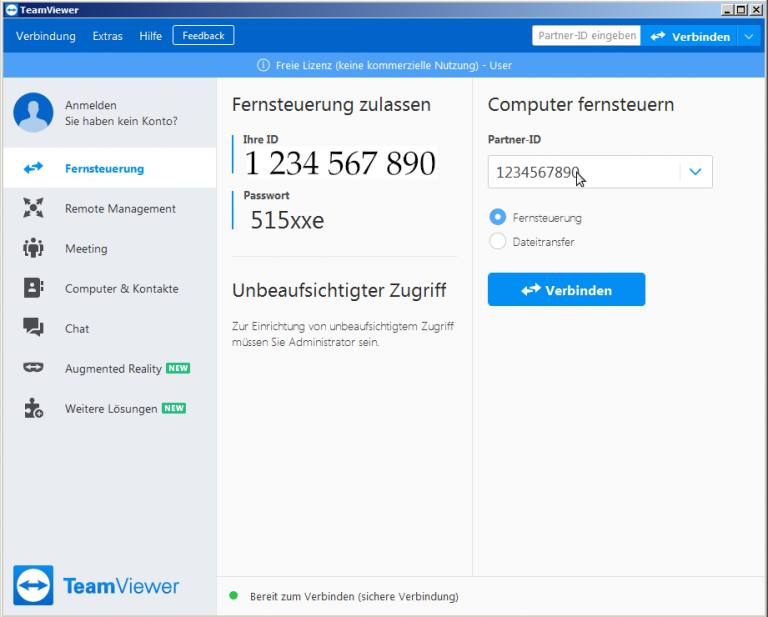

One, through a user account and password, and two, through a one-time access code that someone sitting at the physical computer can supply to the remote person. There are typically two ways to connect to a TeamViewer installation. They have free, non-commercial versions and paid commercial versions that are actively supported to provide remote desktop access to almost any type of computer. It is a publicly available tool that is capable of very good security. TeamViewer is simply a remote access tool.

#Determine if teamviewer hacked update

Patching – Update software, the software is only as good as its configuration. Policies & Procedures – Remove old software and track who has access. Cyber-Physical and Engineering – Why was it possible to set the lye dosing system to 11,100 PPM if the typical dose is 100 PPM?. Access Control – Who has access to the system, it is granular?. There are many ways that this incident could have been avoided. Because it involves off the shelf remote access tools, two, because this story is not about ransomware. This appears to be a fairly low skill type of attack. Another note in the reports indicates that the Threat Actor connected through TeamViewer… the municipality had recently switched to a new remote access software but left TeamViewer in place.Īs we break this report down, we see how that it fits into the Defense in Depth architecture, highlighting just about every aspect. What? The second time? As per The Wall Street Journal’s article, linked below, the first time it is noted that the Operator “didn’t think much of it” because other Operators regularly connect to the system too. How was this modification detected? An Operator noticed the mouse cursor moving on the screen that was interacting with the SCADA system during the SECOND noted intrusion attempt. A water treatment facility was hacked, and a Threat Actor was able to operate the SCADA system remotely to change the dosing rate of lye.

Industrial software, and the corresponding physical systems that it controls, must be protected by an approach that includes considerations for its expected operation.

In modern facilities, industrial software has a direct impact on business continuity, health, safety, and environment.

0 kommentar(er)

0 kommentar(er)